Our Process is complex, so let us break it down…

This is a guide to the process of working with JustAJar to create a custom poster. We are one of a handful of poster shops creating custom posters using the woodcut & letterpress processes, which is a different process than some clients might be used to.

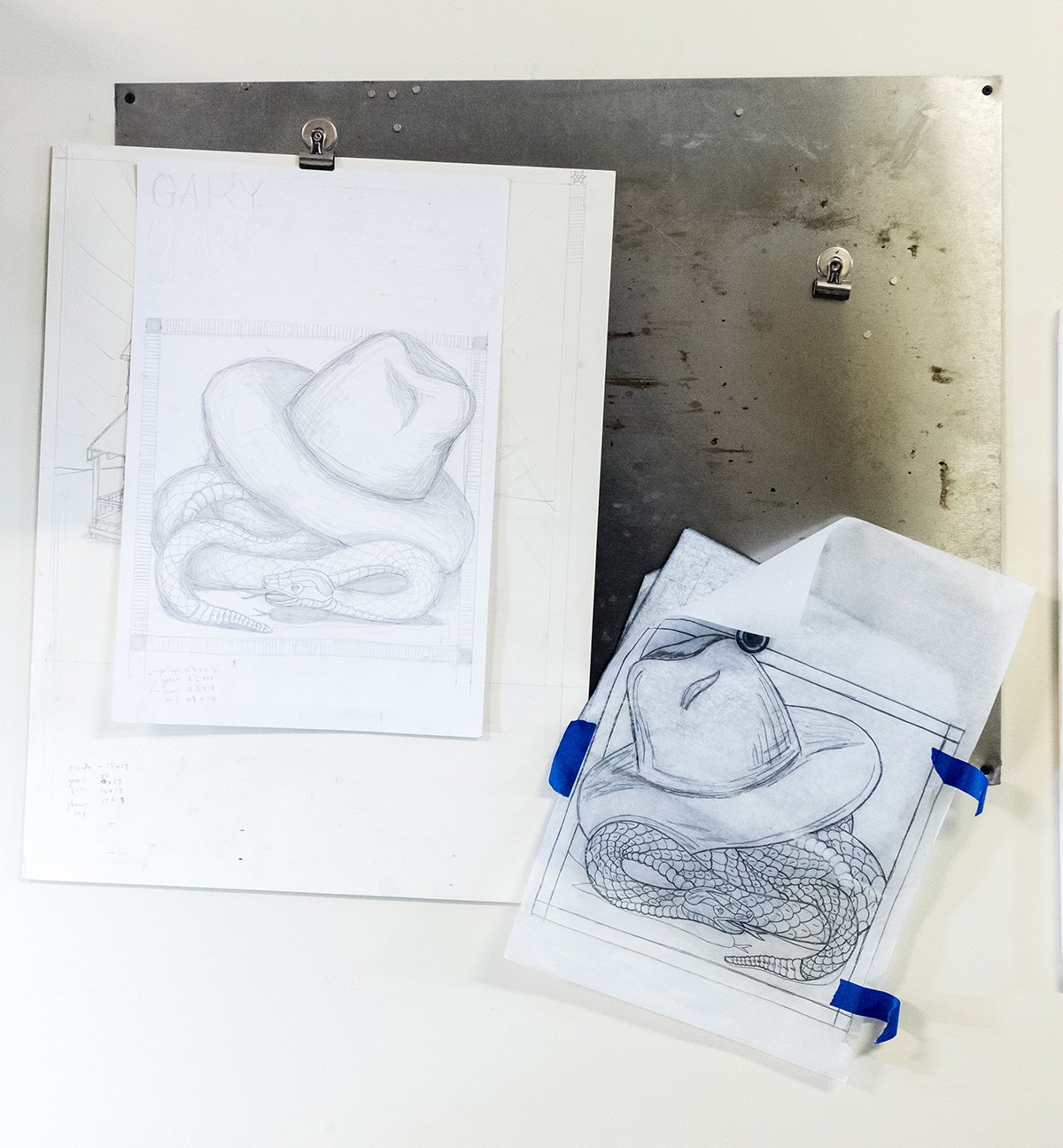

Step 1: Sketch

If you have a theme you are interested in or have seen something we did that you really like you can convey that to us.

The first step is we work on a pencil drawing. This drawing is used to show the client our concept and composition. Our posters utilize the mark-making and textures of woodcut prints. The marks of a pencil and a carving tool are very different. The drawing is merely a rough guide, the final poster will appear much different.

Once the concept sketch is approved we move into production.

The client won’t see the poster design until it is finished.

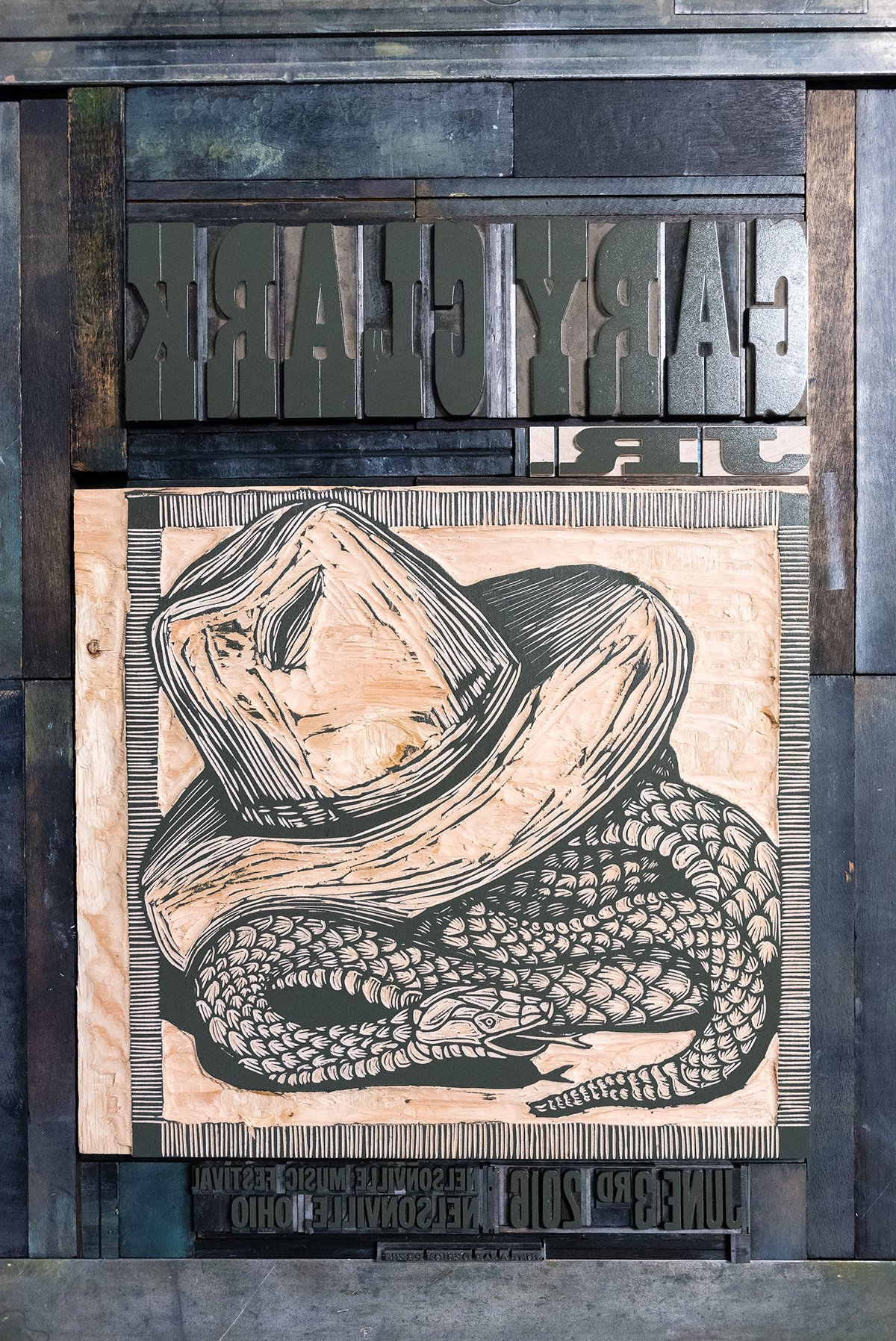

Step 2: Carve

We work using both reductive and multiple-block methods of woodcut printing.

Our posters are typically four to six colors.

The color scheme is carefully planned and each color separation is carved by hand into a block of cherry, birch or luan plywood.

Each color is printed one at a time on our manually cranked flatbed press using rich oil-based inks. We utilize the wood to create unique textures and marks that are often replicated in screenprints through Photoshop filters. But our posters are authentic woodcuts and that quality is apparent when you view the posters in person.

Photography Nate Knobel

Step 3: Print

Text for posters is handset from antique printer’s type.

The smaller type is made from lead and the larger type is from wood. Some of this type dates back 200 years and the worn quality of the type gives the impression on the paper a unique look. All type is meticulously set in reverse, spaced by hand, registered, and locked into the press bed.

Each color is printed individually from a different block of wood, so each color is hand-cranked for another layer of awesomeness. As a result, additional colors add more labor.

We practice sustainability.

Almost all of our equipment is vintage.

Our paper cutter was built in the 1890s, our two presses were built in the 1880s and 1960s, and our type collection has been slowly collected from antique shops and old printer’s basements.

Much of our ink we acquire from the waste of larger print shops.

Our paper comes from a family run paper mill in Michigan that is powered by an on site hydro dam. We reuse the majority of our waste.

Test prints and waste paper we turn into wrapping paper, boxes, book covers, etc.